How to Start 3D Printing: Best Printers for Beginners

3D printing is revolutionizing how we create, design, and innovate. As a beginner, diving into the world of 3D printing can seem daunting, but the right guidance can make the process straightforward and enjoyable. Our guide is here to help you understand the essentials of 3D printing and introduce you to the best 3d printer for beginners. This blog will cover fundamental concepts like what 3D printing is, its working mechanism, and crucial considerations when choosing a 3D printer. We will also guide you through the setup process and provide valuable tips to ensure your 3D printing journey is successful. By the end, you’ll be equipped with the knowledge to begin creating your 3D masterpieces.

Introduction to 3D Printing for Beginners

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process where three-dimensional objects are created layer by layer from a digital file. This technology is versatile and used in numerous fields such as medicine, automotive, fashion, and aerospace. It allows for the creation of complex geometries that are often impossible to achieve with traditional manufacturing methods. Each 3D printer uses different materials such as thermoplastic filaments, resins, or metal powders, depending on the type of technology. As a beginner, understanding the basics of these materials and their applications can help you in selecting suitable 3D printers and materials for your projects.

How 3D Printing Works

The process begins with designing a 3D model using computer-aided design (CAD) software. This digital blueprint is then sliced into thousands of horizontal layers which the 3D printer will create one by one. The printer reads the file and extrudes the material, building the object from the bottom up. There are different types of 3D printing technologies, with the most common ones for beginners being Fused Deposition Modeling (FDM) and Stereolithography (SLA). FDM printers use a continuous filament of thermoplastic material, which is heated and deposited layer by layer. Alternatively, SLA printers use a laser to cure liquid resin into solid objects. This process requires precision and attention to detail but opens up a world of creative possibilities.

Top Considerations When Choosing a 3D Printer

Printer Type: FDM vs. SLA

When selecting a 3D printer, the printing technology is a key factor to consider. FDM and SLA are the two most popular options. FDM printers tend to be more affordable and user-friendly, making them a great choice for beginners. These printers work by heating and extruding a thermoplastic filament to construct objects layer by layer, making them ideal for producing durable, functional parts. In contrast, SLA printers use a laser to solidify liquid resin, offering higher precision and smoother finishes than FDM printers. However, they are typically more expensive and require extra post-processing steps like washing and curing. SLA printers excel at creating intricate, detailed models.

Build Volume and Print Quality

Another important factor to consider is the build volume, which determines the maximum size of objects you can print. For beginners, a print volume of around 200 x 200 x 200 mm is usually sufficient. This allows you to create a variety of items without being too constrained. Print quality is also vital, as it affects the surface finish and detail of the printed object. Look for printers with a high layer resolution, typically around 0.1 mm, which ensures finer details and smoother surfaces. A printer’s stability and construction quality can also impact the final output, so opt for models with robust frames and components.

Setting Up Your First 3D Printer

Unboxing and Assembly

When your 3D printer arrives, the first step is unboxing and assembly. Carefully unpack all the components, checking each one against the manufacturer’s checklist to ensure everything is included. Follow the instruction manual step-by-step, assembling parts like the frame, print bed, and extruder. This process may vary slightly depending on the model, so take your time to understand each step. Some printers come partially or fully assembled, which can simplify the setup process for beginners. However, having a basic understanding of the assembly helps in future troubleshooting and maintenance tasks.

First Print Setup and Calibration

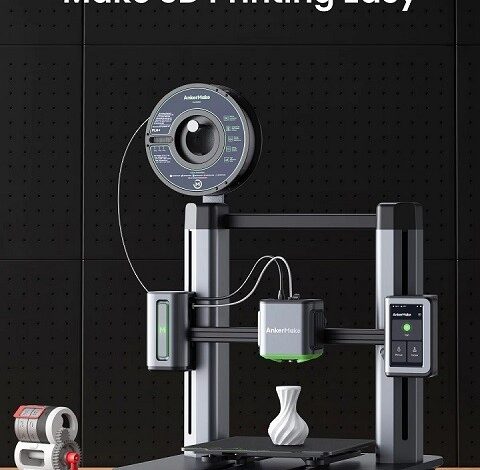

Once your printer is assembled, it’s time to set up for the first print. Start by leveling the print bed, a crucial step for ensuring successful prints. Many modern printers, like the AnkerMake M5, come equipped with auto-leveling systems that make this process easier. Some might require manual calibration using the adjustment knobs under the print bed. Next, load the filament into the extruder, preheat the printer, and load the 3D model file. Most printers come with test prints or sample files; use these to run your first print. Watch closely as the printer begins, making any necessary adjustments on the fly.

Tips for Success with 3D Printing

Troubleshooting Common Issues

3D printing, while rewarding, can come with its share of challenges. Common issues include print warping, layer shifting, and filament jams. Understanding these problems and knowing how to address them is essential. For example, warping can be reduced by ensuring the print bed is properly leveled and heated, while layer shifting might indicate an issue with the belt tension or motor alignment. For filament jams, regular cleaning of the extruder and keeping the filament dry and free from dust can prevent problems. Always refer to your printer’s manual for specific troubleshooting tips related to your model.

Maintenance and Care Tips

Maintaining your 3D printer is key to consistent performance. Regularly clean the print bed, nozzles, and fans to remove any debris or filament remnants. Lubricate the moving parts as recommended by the manufacturer, and check the belts and screws for tightness to prevent mechanical failures. Inspect and replace parts like the print nozzle and build surface periodically, as wear and tear can affect print quality. Keeping software and firmware updates current also ensures you benefit from the latest improvements and bug fixes.

Conclusion

Starting your journey in 3D printing can be incredibly rewarding with the right guidance and tools. Understanding the basics, from how 3D printing works to the considerations in choosing a printer, sets a strong foundation. With models like the AnkerMake M5, beginners have access to advanced features like auto-leveling and AI monitoring, making the process smoother and more enjoyable. Remember, the key to success in 3D printing lies in patience, persistence, and continual learning. As you gain experience, you’ll master the intricacies of this technology, opening up a world of endless creative possibilities. So, equip yourself with a quality 3D printer, follow the setup guidelines, embrace troubleshooting, and start creating wonders, one layer at a time.