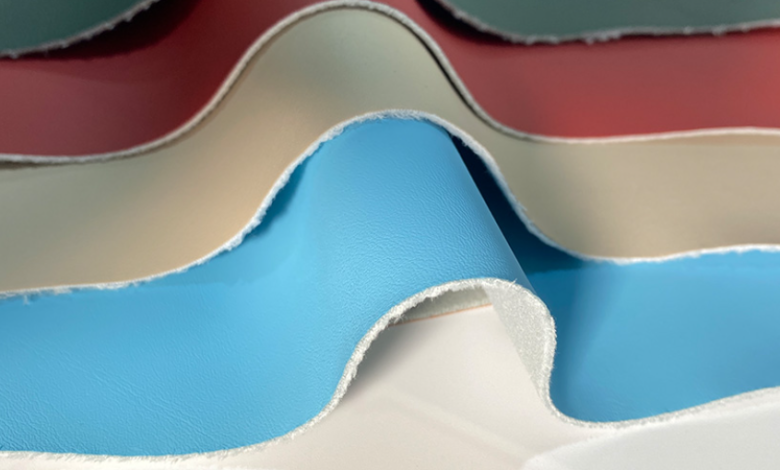

Non Solvent Leather vs Nappa Leather

In today’s leather market, buyers are more informed and environmentally conscious than ever before. As a result, traditional leather types are being compared with newer alternatives that are designed to reduce environmental and health impacts. Among the most talked-about comparisons is that between non solvent leather and Nappa leather. Both materials have distinct characteristics, applications, and production processes that set them apart. Whether you are a manufacturer, retailer, or consumer, understanding the differences between these two leather types is essential for making smart purchasing and sourcing decisions.

What is Non Solvent Leather?

Non solvent leather refers to synthetic or engineered leather produced without the use of harmful solvents like DMF (Dimethylformamide) or other volatile organic compounds during manufacturing. Unlike conventional PU leather, which often relies on chemical solvents for coating and finishing, non solvent leather utilizes water-based or solvent-free technologies. This results in a product that is safer for factory workers, less polluting for the environment, and compliant with global sustainability regulations. Non solvent leather is often used in furniture, automotive interiors, electronics, fashion accessories, and other applications where durability and eco-compliance are required.

Understanding Nappa Leather

Nappa leather, on the other hand, is a high-quality full-grain leather made from the hides of lambs, calves, or other animals. Known for its soft texture, smooth surface, and luxurious feel, Nappa leather is widely used in premium products like car seats, designer handbags, upscale footwear, and fine furniture. It is chrome-tanned and then dyed with soluble color to maintain its softness. While it offers superior comfort and elegance, Nappa leather requires significant water and chemical input during tanning and dyeing, which can raise concerns from an environmental standpoint. Still, it remains a benchmark for quality in natural leather.

Environmental Considerations

One of the most significant differences between non solvent leather and Nappa leather lies in their environmental impact. Non solvent leather is considered a more sustainable option because it eliminates the need for toxic solvents in the production process. It also typically requires less water and energy. Manufacturers can reduce greenhouse gas emissions and prevent hazardous waste discharge by using this eco-friendly material. In contrast, the production of Nappa leather involves animal agriculture, heavy water consumption, and chemical tanning, all of which contribute to environmental degradation. Brands focused on eco-conscious production increasingly favor non solvent alternatives for this reason.

See also: Design That Works: What Real Homes Really Need Today

Durability and Maintenance

In terms of durability, both non solvent leather and Nappa leather offer advantages. Non solvent leather is engineered to be water-resistant, UV-resistant, and resistant to abrasion. It holds up well in high-use environments such as automotive interiors or commercial furniture. Cleaning is generally easier, requiring only a damp cloth and mild detergent. Nappa leather, while soft and elegant, is more susceptible to staining, scratching, and wear over time. It often requires regular conditioning and specialized cleaners to maintain its appearance. Therefore, for projects where low maintenance is a priority, non solvent leather is a more practical choice.

Aesthetic and Tactile Qualities

When it comes to appearance and feel, Nappa leather has a rich, natural grain that synthetic materials often try to replicate. It offers a warm, buttery touch and a timeless elegance that appeals to luxury markets. Non solvent leather has come a long way in replicating these qualities, with advanced texturing and dyeing techniques that mimic natural leather closely. Some high-end synthetic leathers are virtually indistinguishable from real leather in both look and feel. However, purists often still prefer the authenticity and natural irregularities found in Nappa leather. The choice often depends on the intended brand image and product positioning.

Cost Differences and Market Positioning

Cost is another factor that distinguishes these two leather types. Nappa leather is expensive due to its animal source, labor-intensive tanning, and limited availability. It is often reserved for high-end products where price is less of a concern. Non solvent leather is more affordable, especially at scale, making it a go-to option for manufacturers aiming for quality without high material costs. It also allows companies to maintain price competitiveness while offering eco-friendly products. For businesses aiming to balance sustainability with profitability, non solvent leather can provide significant advantages over premium animal-based leathers like Nappa.

Applications in Various Industries

Both non solvent leather and Nappa leather have broad applications across multiple industries. Nappa leather is the preferred choice in the luxury segment—automotive brands use it for upscale car interiors, while fashion houses feature it in premium bags, jackets, and shoes. Non solvent leather, on the other hand, is versatile and used in a wide array of industries including healthcare, hospitality, office furniture, and consumer electronics. Its antimicrobial, fire-resistant, and anti-yellowing properties make it ideal for demanding environments. As sustainability regulations tighten, more industries are switching to non solvent options without sacrificing quality or aesthetics.

Regulatory Compliance and Certifications

Companies looking to export or distribute leather-based products globally must adhere to international standards like REACH, RoHS, and California Proposition 65. Non solvent leather is designed to meet these regulations easily, making it a safer choice for businesses with global distribution channels. It is also easier to get certified under eco-labels like OEKO-TEX or Global Recycled Standard. Nappa leather, unless sourced from responsible tanneries, may pose challenges in achieving such certifications due to the use of chromium and other heavy metals during processing. From a compliance standpoint, non solvent leather offers a more straightforward path.

Making the Right Choice for Your Brand

Choosing between non solvent leather and Nappa leather depends on your brand goals, target market, and product requirements. If your focus is on luxury, craftsmanship, and tradition, Nappa leather remains a strong candidate. However, if your brand values sustainability, affordability, and regulatory compliance, non solvent leather is a future-forward alternative that aligns with evolving consumer expectations. With innovations in synthetic leather continuing to improve texture, flexibility, and environmental performance, non solvent leather is fast becoming the smart choice for modern manufacturing.

Conclusion

The leather industry is undergoing a transformation fueled by innovation, environmental awareness, and consumer demand for safe and sustainable materials. The comparison between non solvent leather and Nappa leather highlights the evolving choices available to manufacturers and brands today. While Nappa leather continues to represent luxury and tradition, non solvent leather provides a powerful alternative that balances performance, safety, and sustainability. As industries look to the future, non solvent leather is set to become a leading material in responsible design and manufacturing.